MANUFACTURING & JOB SHOP

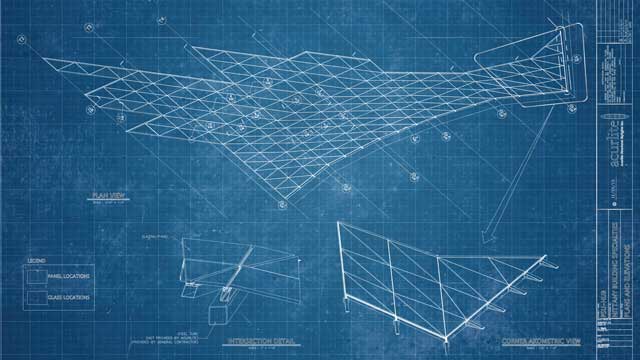

CUSTOM DESIGN AND FABRICATION

Take advantage of Acurlite’s design and fabrication capabilities. Through years of designing and fabricating complex skylights and overhead glazing projects, Acurlite has developed a vast knowledge of custom fabrication. Acurlite also has specialized machinery to assist in this custom fabrication process.

Let our staff of industry professionals assist you in your fabrication needs. By choosing Acurlite as your vendor / partner for custom fabrication you can instantly expand your own production capabilities while still being confident an industry professional is completing your project. Acurlite guarantees quality and craftsmanship that our industry demands.

Elumatic CNC 5-axis profile machining center

- 5-axis CNC technology package delivers the best possible efficiency for every imaginable machining task.

- Performs operations, such as routing, drilling, tapping, thread milling, notching and sawing, are while the profile bar is stationary to protect the profile surfaces.

- On-board tool magazines ensure that tool changing times are kept short, thereby optimizing machining cycles.

- Magazine can be fitted with 14 tools and one saw blade with a diameter of 400 mm.

Elumatic Double Headed Miter Saw

- Pivoting range inwards, pneumatically, 90° – 45° Manually up to 22.5° inwards and up to 140° outwards with digital display

- Tilting range inwards, pneumatically, 90° – 45° Intermediate angles manually adjustable with digital read-out display and turret stop

- A large saw blade diameter and optimal use of the saw blade offer an ideal cutting capacity for all cutting variations.

- External dimension cuts at all angle positions. No length calculations are necessary when cutting profiles of different heights.

- Universal pivoting and tilting of both saw units allows cutting of high and wide profiles as well as every type of compound miter.

Many profiles can be cut without support blocks. This is a big advantage when cutting special angles.

Calypso Hammerhead CNC Abrasive Water Jet Cutting System

- Calypso CNC Control – 5’ x 10’ work area, Sheet Steel, Sheet Aluminum, and Sheet Plastics.

- Painted, finished, or mill material.

Baykal 150 Ton Press Brake

- 12 ft. length.

- Break form steel and aluminum up to 1/4” thick and 120” long.

- Ideal for multi-bending of complex forms, as well as for volume production which require constant repeatability.

- Bend accuracy and repeatability at least five-fold higher than a conventional press brake.

Baykal 10’ Guillotine Shear

- Steel and aluminum up to 1/4” thick and 120” long.

Manufacturing Process

Here’s a quick look at how Acurlite delivers unique designs, with our state-of-the-art Manufacturing Facility.

Take the next step

Contact Acurlite to discuss your project.