ENGINEERING & DESIGN ASSIST

no design is too complex

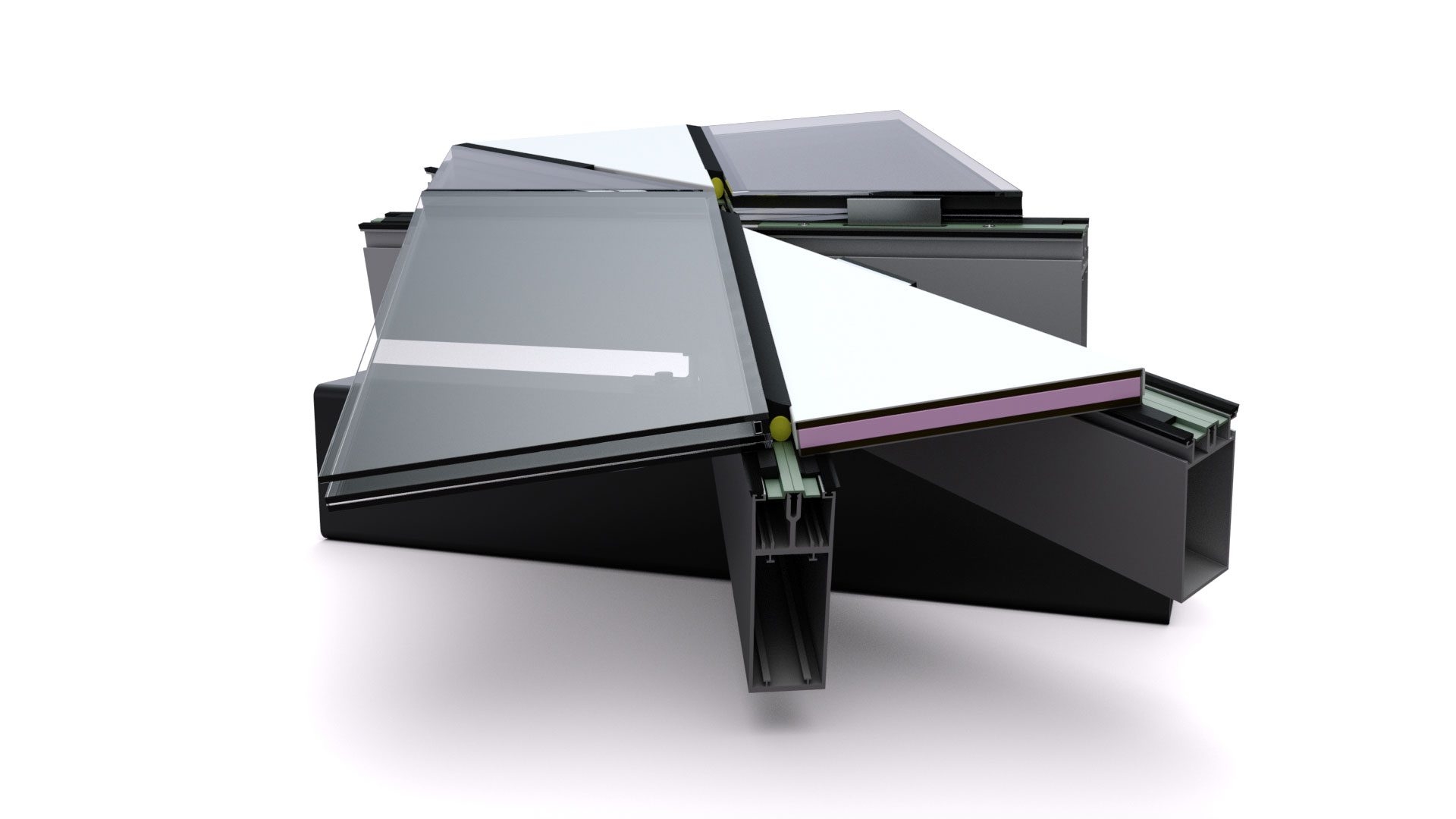

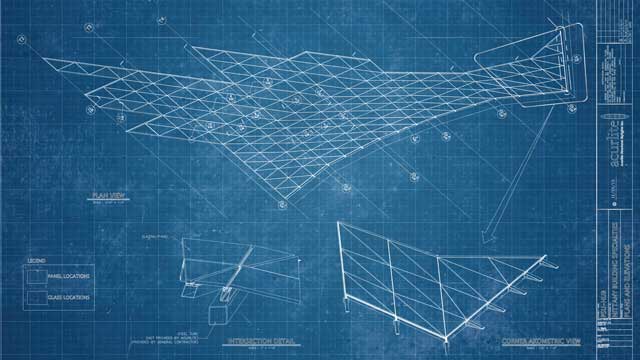

Whether for custom design requirements or production of submittal drawings, the engineering process is vital to achieving a quality product and installation. Acurlite’s attention to detail and innovative thinking sets us apart from the competition. Acurlite’s engineering and design staff have countless years in the skylight industry working on monumental, highly complex designs.

Pictured: Penn State University HUB, University Park, PA

State-of-the-art 3D and BIM modeling brings concepts to life before they leave the drawing board, saving time and money. The Penn State HUB Project is visualized in the design phase.

VIEW THE SPACE IN 360°

Click the 360° image below

Click, touch, or pinch the image below to get a virtual view of the space!

Take the next step

Contact Acurlite to discuss your project.